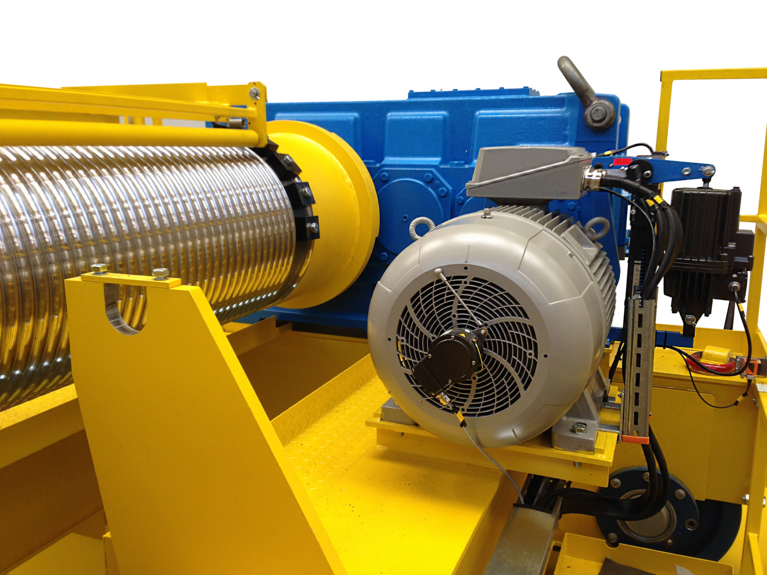

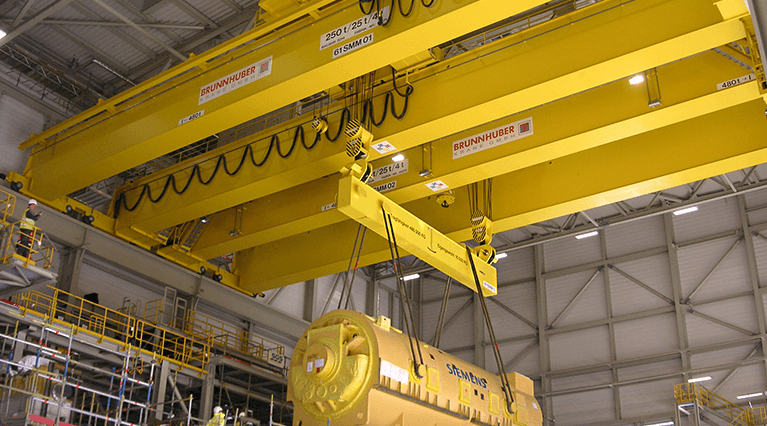

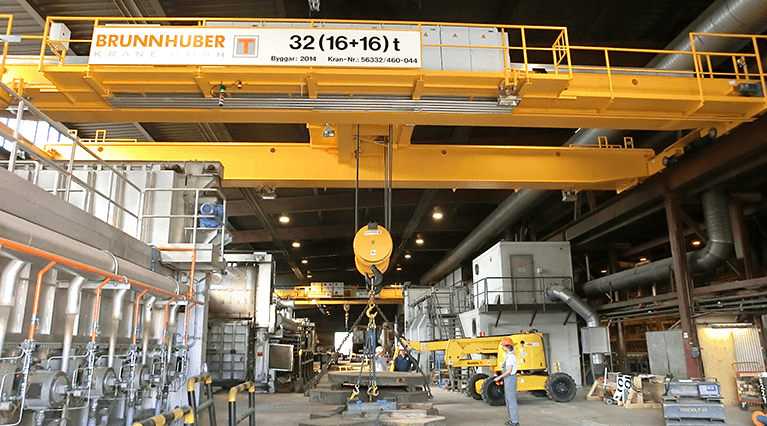

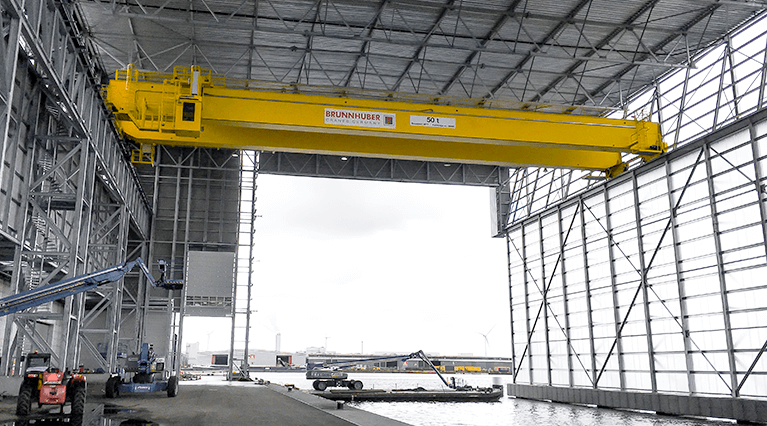

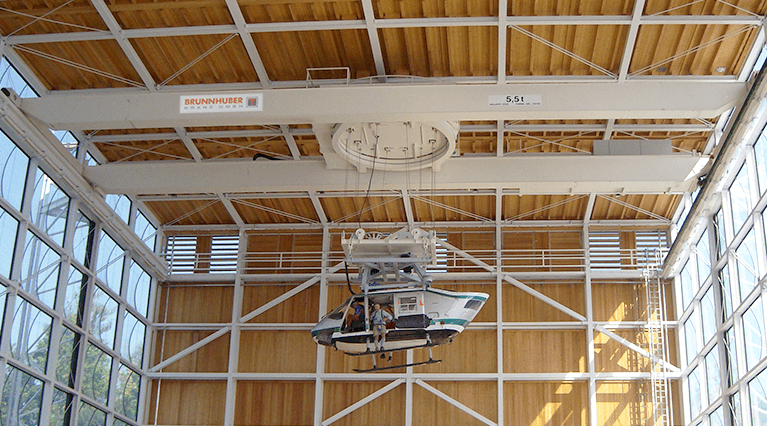

The BRUNNHUBER winch is the core of more than 5.000 crane installations operated worldwide and has now been processed and further developed as an individual compo- nent for our customers in response to the high demand it.

It is constructed according to a modular concept and can be configurated to your needs. When developing it, we par- ticularly focussed on robust execution, simple maintenance and reliable and durable operation. We would be pleased to submit an individual offer to you

- Capacity: from 15.000 kg to 250.000 kg

- Lifting height: from 6,0 m to 200,0 m

- Classification: from 1Am (M4) to 5m (M8)

- high quality standard components

- robust and stable construction

- easy maintenance and optimal service accessibility

- large lifting heights

- adaptable and configurable winch technolog

- easy integration into your existing crane and trolley design

- robust cylindrical hoist gear for heavy duty use

- powerful hoisting motors in compliance with latest Energy Directives with rotary encoder and temperature monitoring – ideal for inverter operation

- elastic and rupture-proof coupling between motor and gearbox

- standardized drum brakes, robust and highly reliable in severe operating conditions

- BRUNNHUBER cable drum with flanged pulleys and optimized rope grooves

- BRUNNHUBER bottom hook block with optional load hook executions

- BRUNNHUBER top hook block and rope balancing

- modern low-wear ropes

- overload protection with optional load displays

- limit switch for top and bottom hook position

- mechanical emergency hoist limit switch for the highest hook position

- rope overflow protection

- second brake at the drive side (as motor brake or as drum brake)

- disk brake at the drive side as safety brake

- flanged wheel brake at the cable drum

- rotary encoder instead of gear limit switch at the cable drum

- frequency inverter with energy recovery

- programmable logic control

- complete trolley

- overspeed monitoring at the cable drum

- support rollers under the flanged wheel